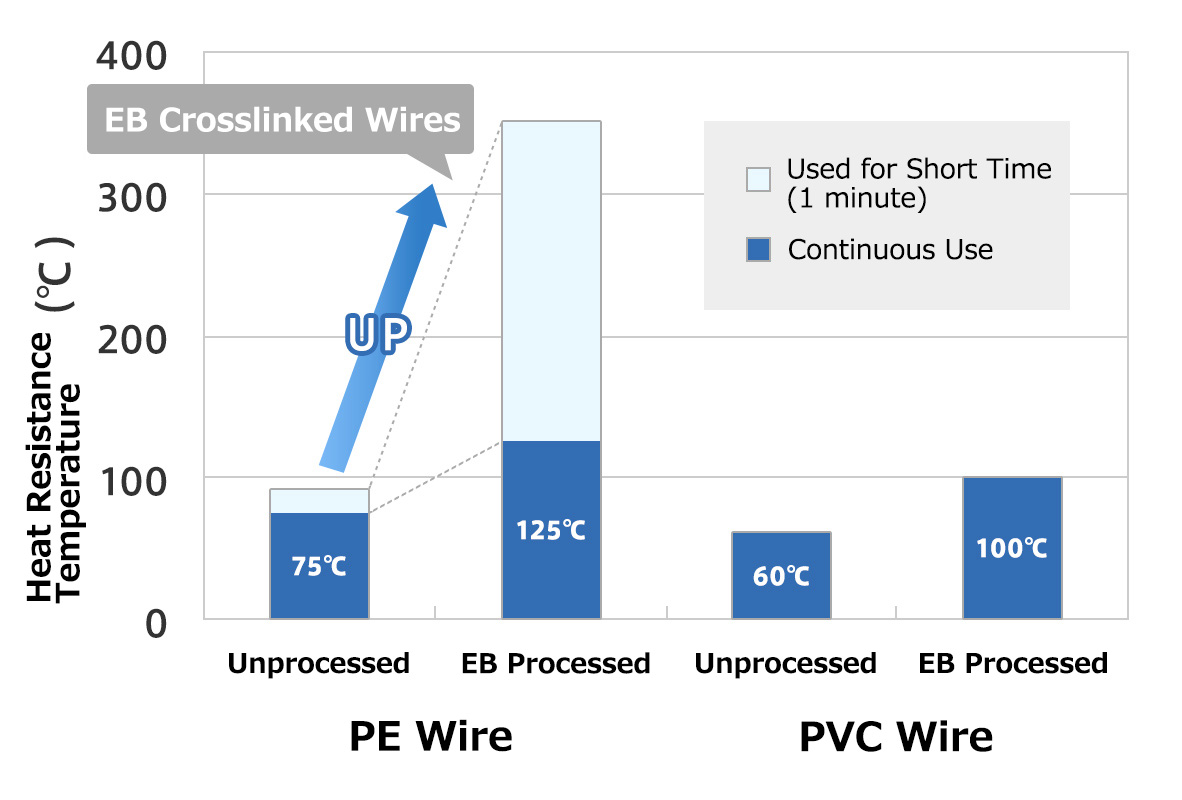

Since the heat resistance of electron beam (EB) crosslinked wire coating is improved, these wires are used in high-temperature environments such as around automotive engines.

Untreated PE-coated wires can withstand temperatures of about 90℃, but when crosslinked by electron beam the wires become able to withstand continuous temperatures of 125℃ and short periods of 350℃.

This also prevents the coating from melting during soldering, greatly facilitating workability.

Improving the wire's usable environmental temperature also contributes to smaller devices and greater reliability.