Controlling Bubbles in Foam Sheets

Electron Beam (EB) Crosslinking

Chemical Crosslinking

Foaming Degree Depends on the Crosslinking Method

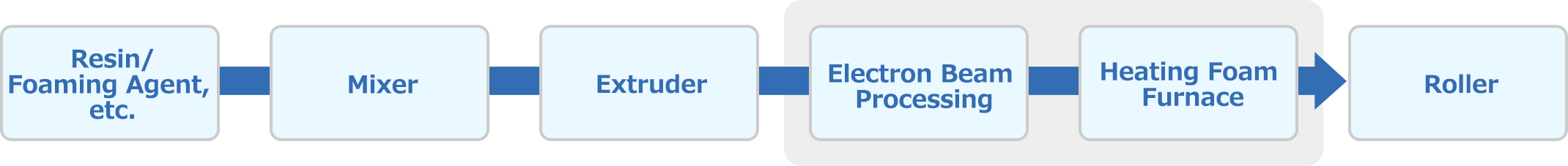

Example of Foam Manufacturing Process

Producing a High-Quality Foam Sheet

Foam sheets are manufactured by mixing the base resin with a foaming agent in a mixer, extruding it as a sheet using an extruder and then passing through crosslinking and foaming processes.

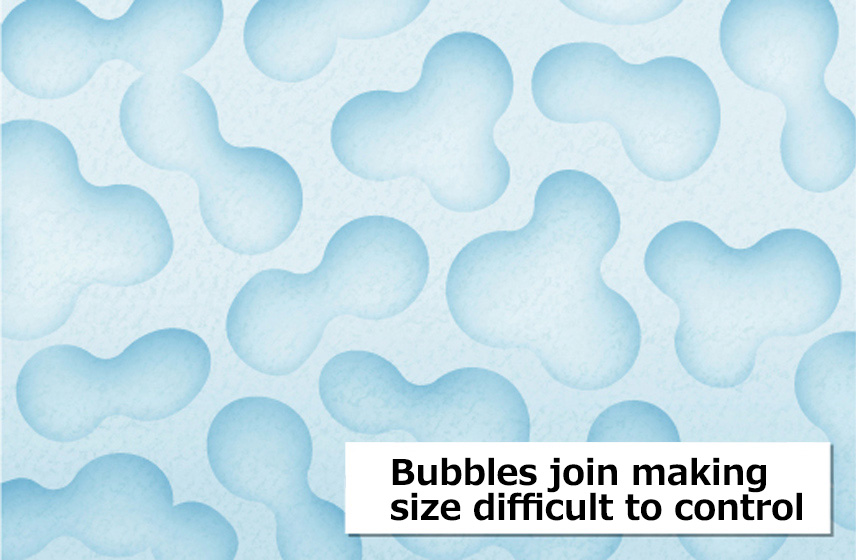

In the case of generic chemical crosslinking, adding heat for crosslinking initiates decomposition of the foaming agent, foaming and crosslinking at the same time. This makes it difficult to control the bubbles that are formed.

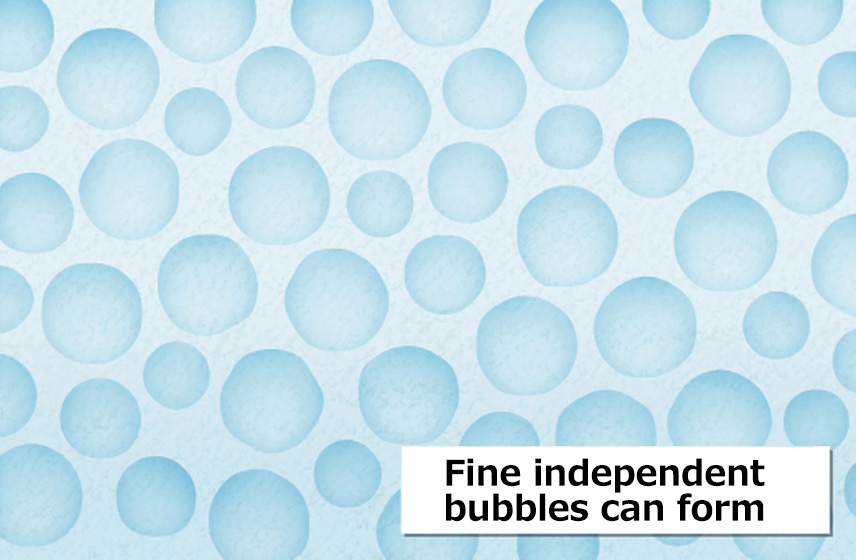

On the other hand, with electron beam crosslinking, since temperature gains during crosslinking are low, it is possible to perform crosslinking and foaming as separate processes, simplifying foaming control.

Bubble size can be controlled depending on the degree of crosslinking, so it is possible to manufacture high quality sheets that achieve high smoothness with fine independent bubbles by raising crosslinking on the surface and high shock absorption with larger bubbles by lowering internal crosslinking for the interior. This is useful for automotive interior materials and insulation.