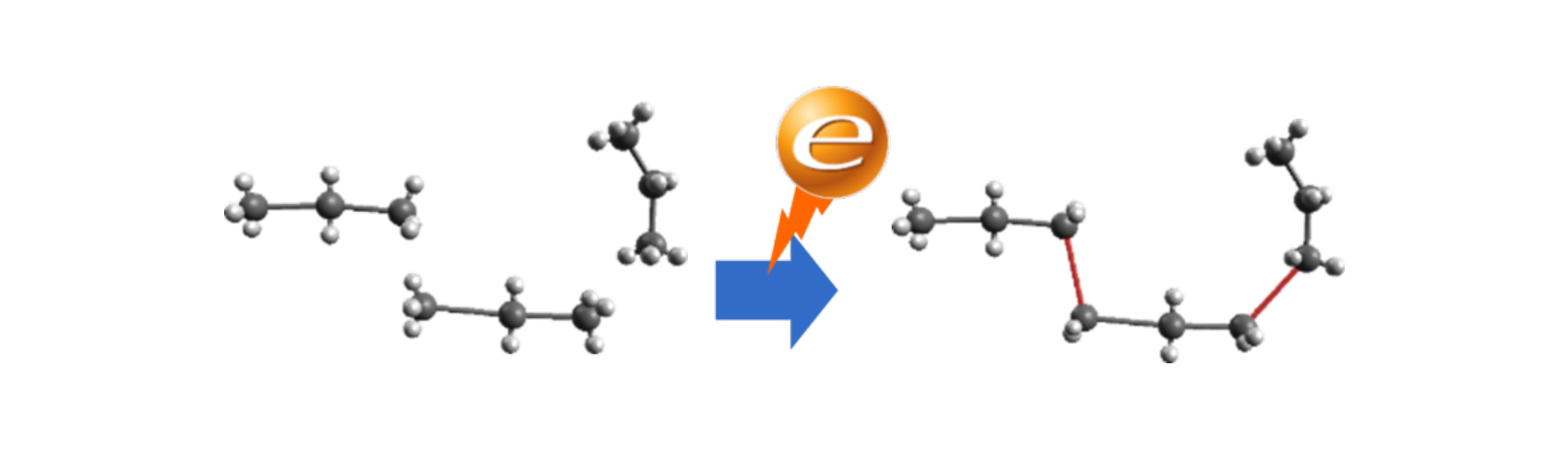

EB Curing Principles

Electron beams instantly bond monomers and oligomers applied to the base material surface to form coatings.

Since this curing method does not require additives, it has excellent weather resistance and other properties.

Comparison of Curing Methods

| Electron Beam Curing | Heat Curing | UV Curing | |

|---|---|---|---|

| Added Catalyst | Not Needed | Needed | Needed (Photoinitiator) |

| Curing Temperature | A few degrees Celsius above room temperature | 80~250℃ | 40~80℃ |

| Curing Atmosphere | Inert (Nitrogen) Gas | Air | Air |

| Curing Time | Less than 1s | A few seconds to tens of seconds | A few seconds to tens of seconds |

| Solvent Dilution | No solvent possible | Needed | No solvent possible |

| Curing Thickness | A few μm to a few mm | No limit | 10~100μm |

| Energy Efficiency | High | Low | Low |

Electron beam cured resins can reduce environmental burdens since they do not require solvent dilution or added catalysts such as polymerization initiators.

With a high crosslinking density, electron beam cured resins feature superior wear resistance and durability.

However, since these resins are generally cured in an inert gas environment, the base material is also affected by the electron beam, so caution is required.