Medical Devices

Medicine Containers

Beverage Containers

Exposure to electron beam irradiation will kill microbes (sterilization), making this technique beneficial for medical devices, medicine containers, food packaging, and cosmetic containers among many other products.

Electron beam processing allows for high-capacity product treatment. The sterilization does not leave a residue, making EB a preferred treatment versus other methods.

EB Sterilization Principles

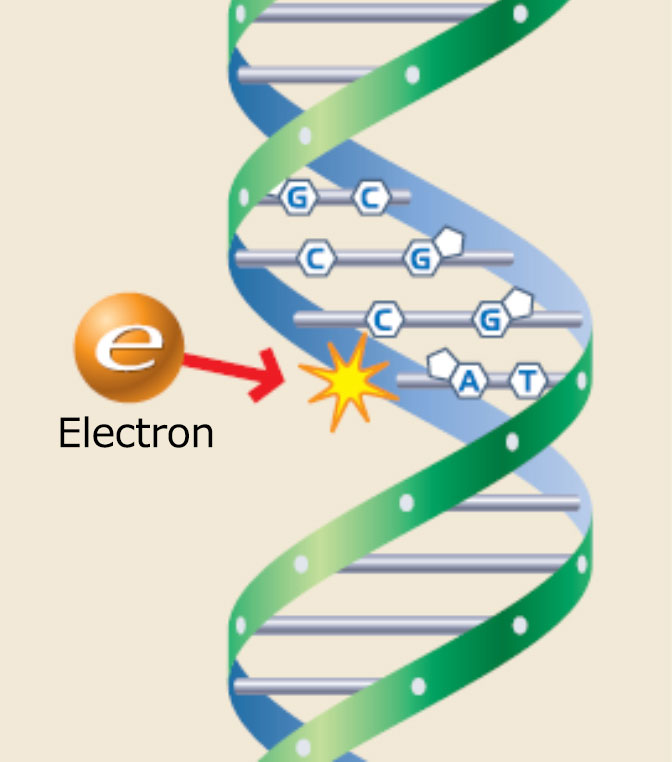

Direct Effects

Directly damages the double-helix

structure of the DNA.

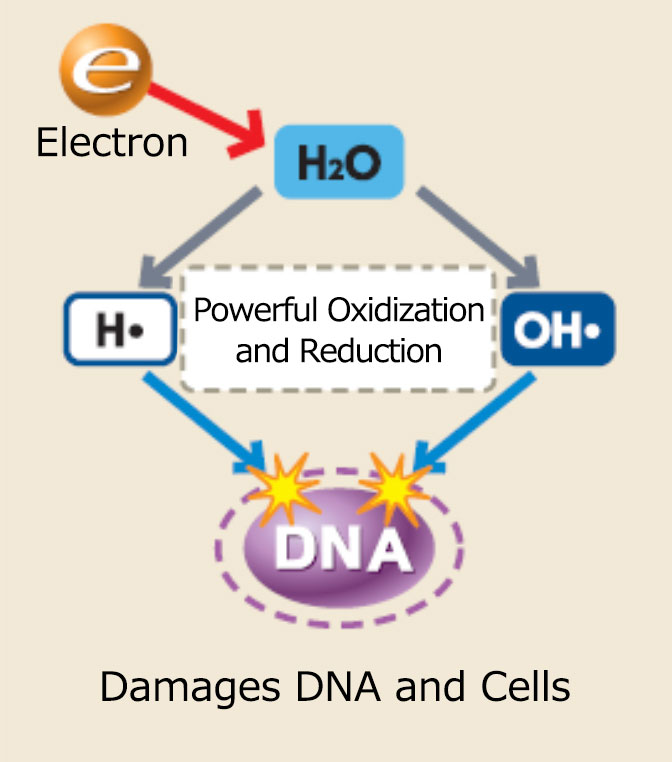

Indirect Effects

Oxidizes and reduces

materials damaging the cells.

DNA is damaged by two effects of exposure to electron beams.

The first effect is direct damage to caused to the double-helix structure of DNA. The second is that electron beams also split water molecules in cells, generating radicals that cause indirect damage.

Comparison of Sterilization Methods

| Electron Beam | Gamma Ray | Ethylene Oxide Gas |

High Pressure Steam | |

|---|---|---|---|---|

| Penetration | Yes | Yes | Requires that gas can penetrate | Requires that steam can penetrate |

| Treating Temperature | Room temperature | Room temperature | 38~60℃ | 120℃ |

| Sterilization Confirmation Method | Dosage check | Dosage check | Parameter check or BI test |

Parameter check or BI test |

| Treatment Time | Seconds | Hours | 10 hours | Hours |

| Post-processing | Unnecessary | Unnecessary | Degassing | Drying |

| Residue | None | None | Potential gas residue | None |

Benefits of Electron Beam Sterilization

| ● | Process products at room temperature, allowing sterilization even when sensitive to heat |

| ● | Able to instantly sterilize |

| ● | Safe; does not leave harmful residue |

| ● | Handle easily without pre- or post-processing |