Effect of Irradiation Atmosphere

Posted date:June 01, 2023Last updated:January 18, 2024

The atmosphere in most industrial electron beam irradiation applications is typically ambient conditions.

However, in the cases of curing paints and inks, irradiation is conducted in an inert gas atmosphere. The reason for this is that only the surface layer of the coating film reacts with oxygen in the air, preventing the curing reaction from progressing. Also, in the case of crosslinking reactions, irradiation in the air inhibits the crosslinking reaction in the surface layer as well as the curing reaction.

Effect of Irradiation Atmosphere on Crosslinking Reaction

In electron beam irradiation, which is industrially used for crosslinking of wire coating materials and automobile tires, the irradiation atmosphere is air, but examinations are also being conducted to accelerate crosslinking reactions by changing the irradiation atmosphere. When high-density polyethylene (HDPE) is irradiated in acetylene or acetylene + chlorotrifluoroethylene, the crosslinking reaction is considerably accelerated, but since these atmospheric gases do not enter the depth of 300μm or more, the internal gel fraction has been obtained with no significant difference.

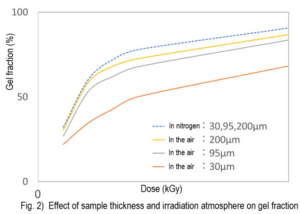

In other words, it can be said that the effect of the irradiation atmosphere on the crosslinking reaction is significant only for thin films of 300μm or less in thickness.

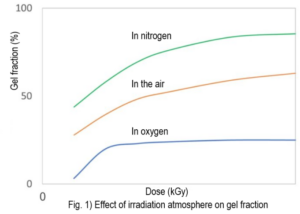

To confirm the effect of irradiation atmosphere on crosslinking of thin films, we examined the relationship between dose and gel fraction due to differences in irradiation atmosphere using a 40 µm film of ethylene vinyl acetate (EVA) [vinyl acetate (VA) content 10%], as shown in Figure 1. The results showed that the crosslinking effect was in the order of nitrogen > air > oxygen. This is because crosslinking of polymers is a radical reaction, and the presence of oxygen inhibits the cross-linking reaction due to the reaction between radicals and oxygen and the recombination of radicals.

As shown in Figure 2, low-density polyethylene (LDPE) with three different thicknesses (30, 95, and 200μm) was irradiated with electron beams in air and nitrogen, and the change in gel fraction was examined. As a result, the gel fraction increased with increasing sample thickness when irradiated in air but was not affected by sample thickness when irradiated in nitrogen, suggesting that oxygen inhibition affects only the surface layer of the sample. This result was also confirmed by differences in carbonyl group absorption in FT-IR and surface oxygen content in ESCA.

Effect of Curing Reaction

Since radical polymerization is dominant in the EB curing reaction of the acrylic hard coating agent used in this study, the presence of oxygen stops the growth of the polymerization chain by reacting with radicals, the active species in the chain reaction. Therefore, the EB curing reaction is conducted in an inert gas, and nitrogen gas is generally used. However, the use of nitrogen gas is not desirable because it leads to higher running costs. For this reason, some efforts have been made on the part of the electron beam irradiation system to reduce the consumption of nitrogen gas by recycling part of the nitrogen put into the electron beam irradiation chamber, thereby reducing the running cost.

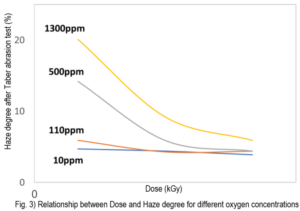

On the EB cured resin side, it is desirable to cure even if the purity of nitrogen gas is poor. Therefore, as shown in Figure 3, we varied the residual oxygen concentration in nitrogen from 10ppm to 1300ppm and examined the difference in haze degree after the Taber abrasion test. The effect of residual oxygen concentration is seen at the low dose side, but as the dose increases, the effect of residual oxygen concentration becomes smaller. This effect was also confirmed by the change in the double bond of the acryloyl group in FT-IR; therefore, the residual oxygen concentration in the irradiation atmosphere should be less than about 500 ppm.

Summary

Since both crosslinking and curing reactions are radical polymerization reactions, they are affected by oxygen in the air, resulting in a polymerization stoppage reaction, but this is limited to the surface layer.

In the crosslinking reaction, the influence of the surface layer is often negligible for materials with thicknesses on the order of mm, such as wire coating materials and foamed materials, so the irradiation atmosphere can be considered to be atmospheric. However, since the characteristics of the surface layer are important in the curing reaction, an atmosphere in nitrogen should be used to prevent oxygen inhibition, and the residual oxygen concentration should be 500 ppm or less.

[Inquiry]

NHV Corporation

Please inquire through the inquiry form.