While maintaining the reliability that has been cultivated in Japan for many years,

We have reduced space, reduced costs, and improved maintainability.

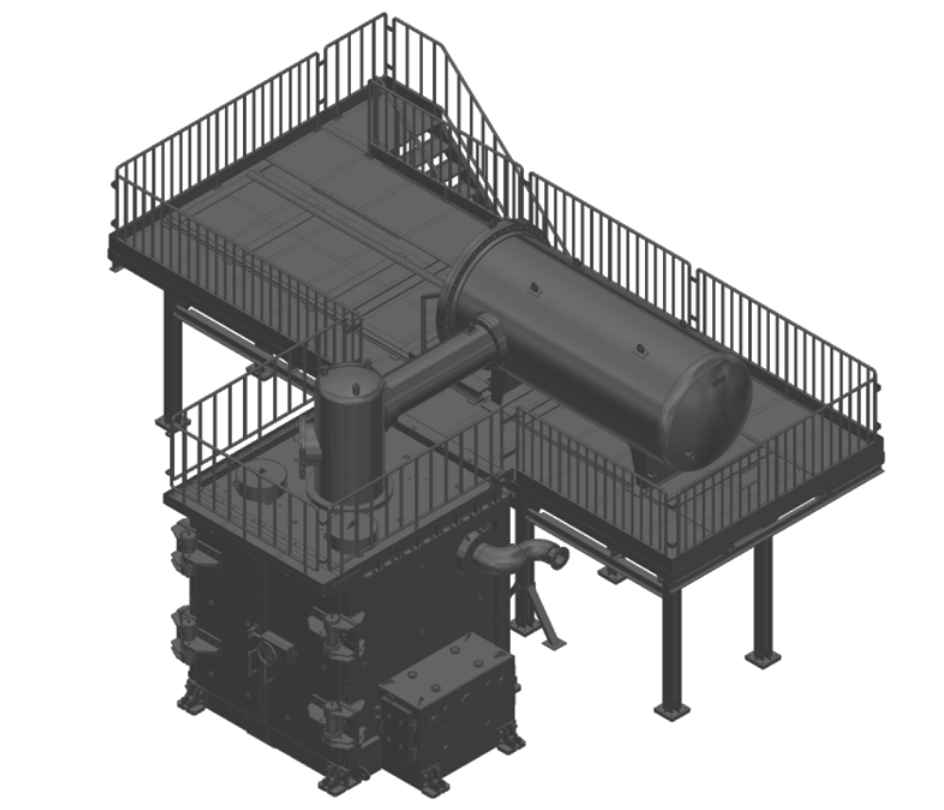

Comparison of New Product(EB-XW) vs. Conventional EPS

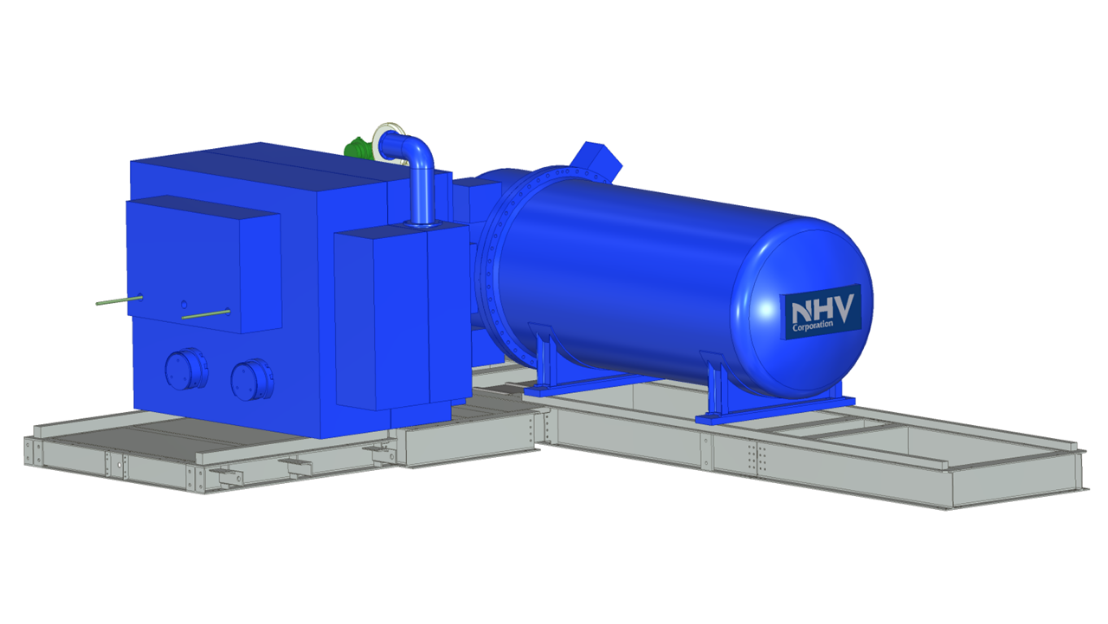

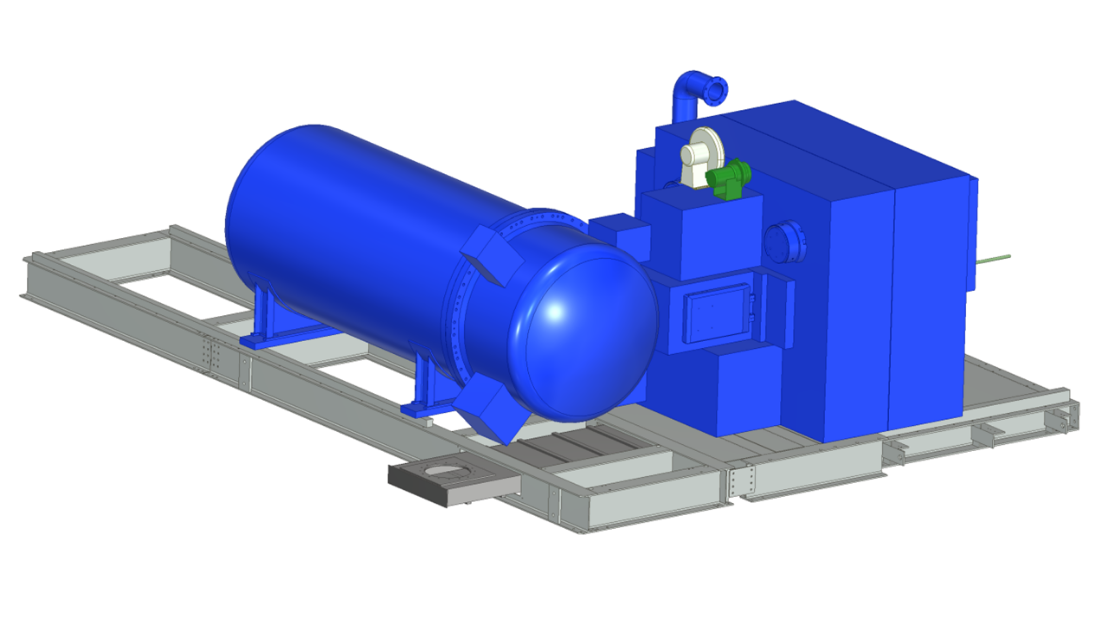

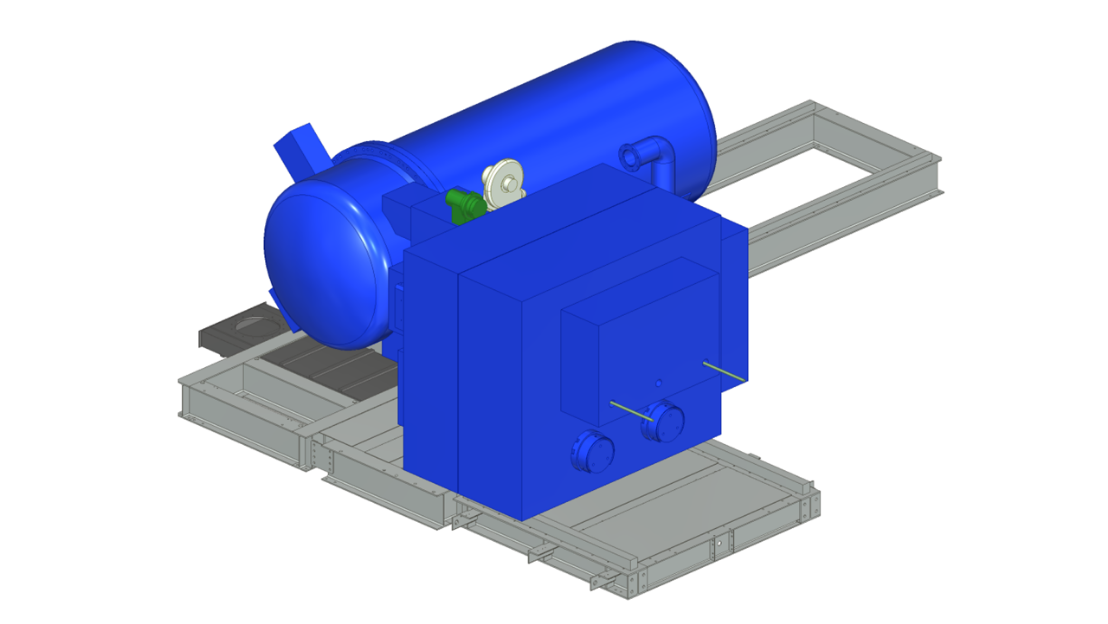

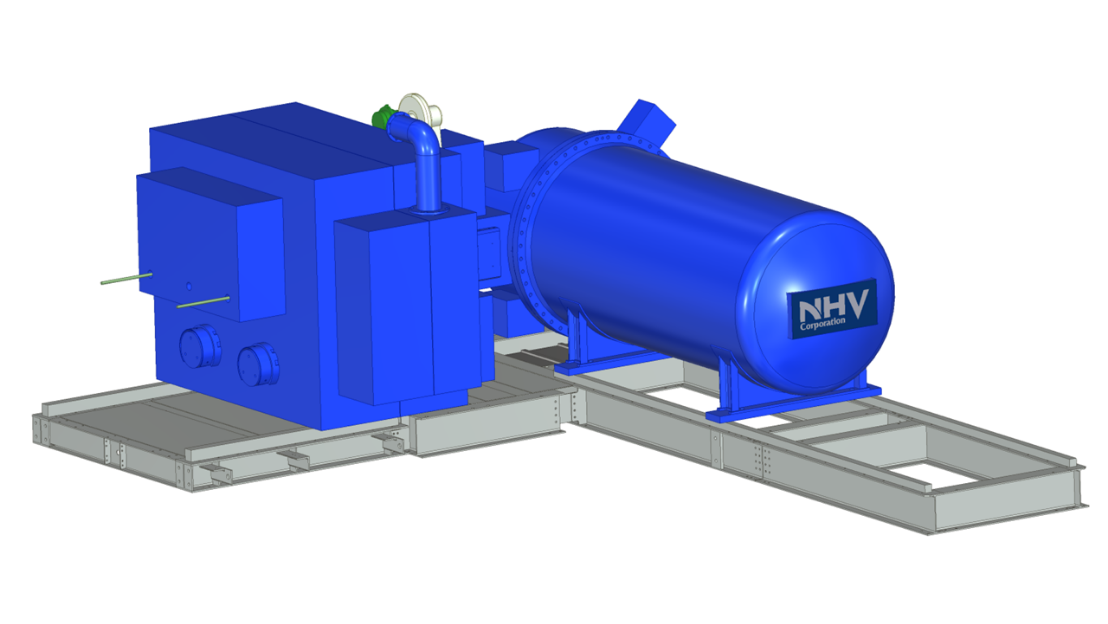

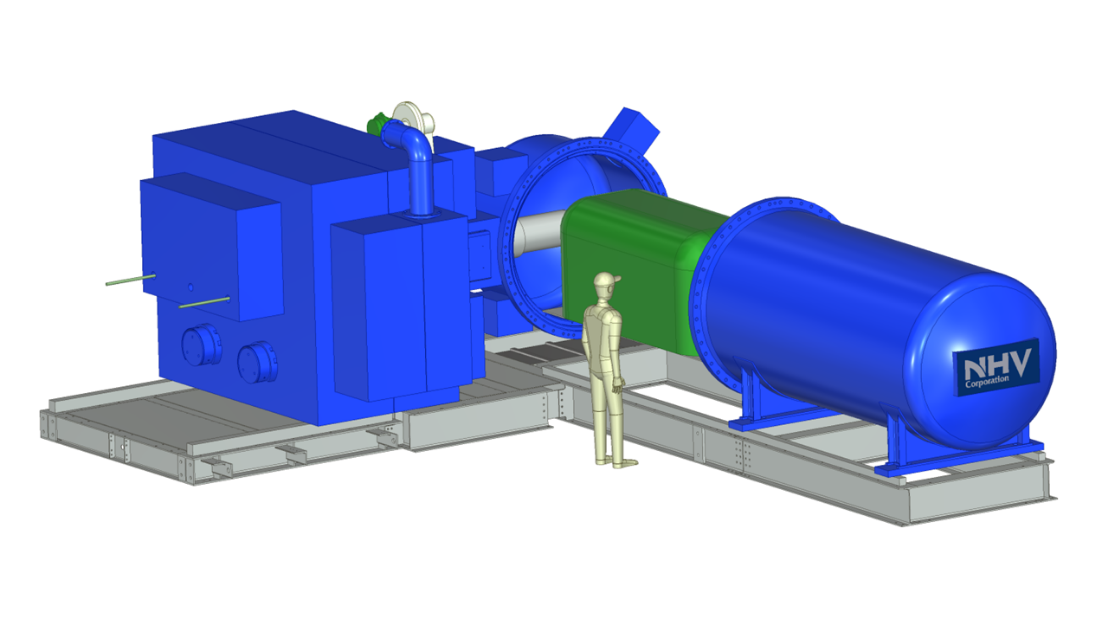

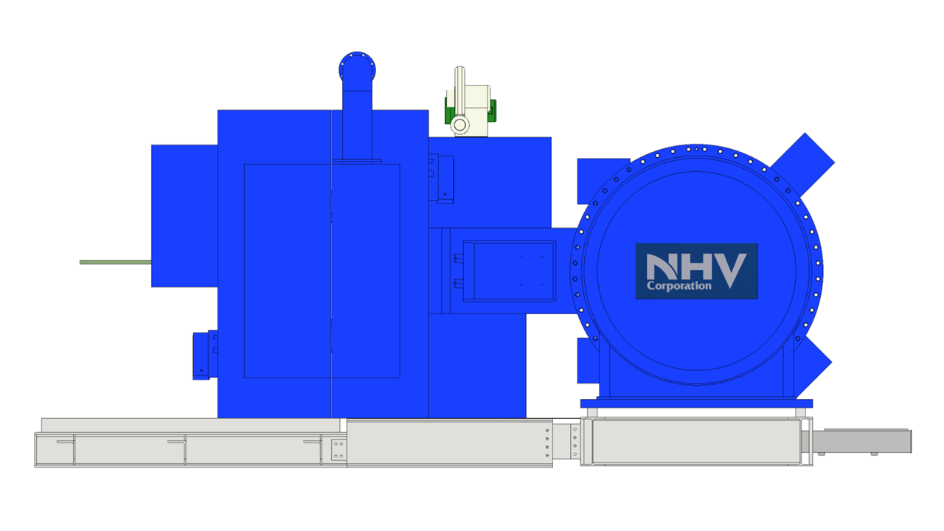

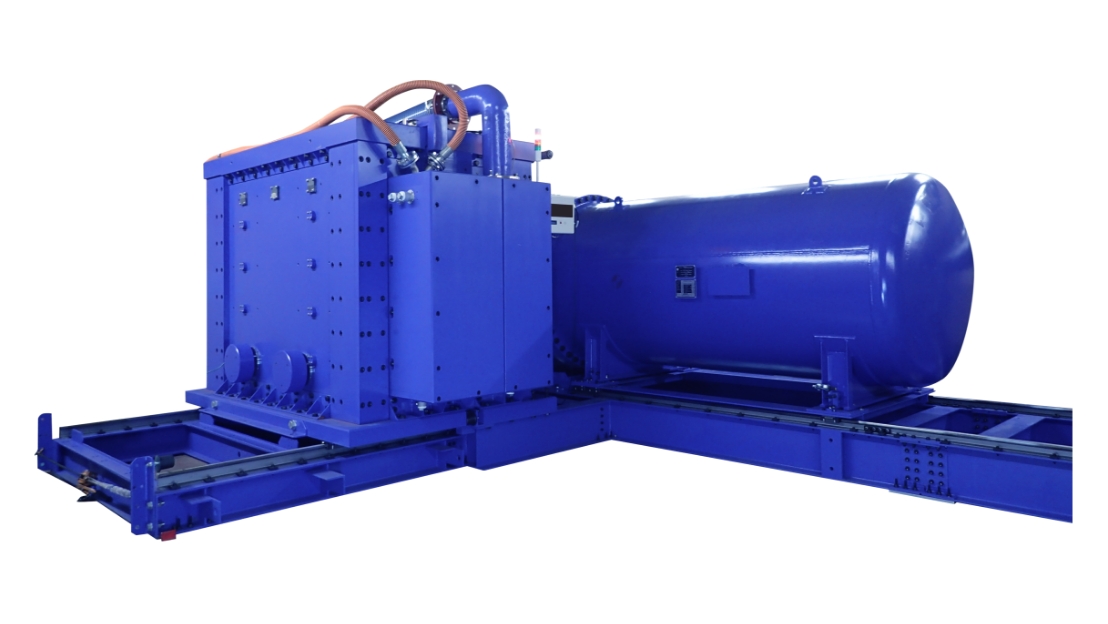

1Reduce Space by Combining the Accelerator and DC Power Supply Tanks

It is 30% smaller than the conventional EPS.

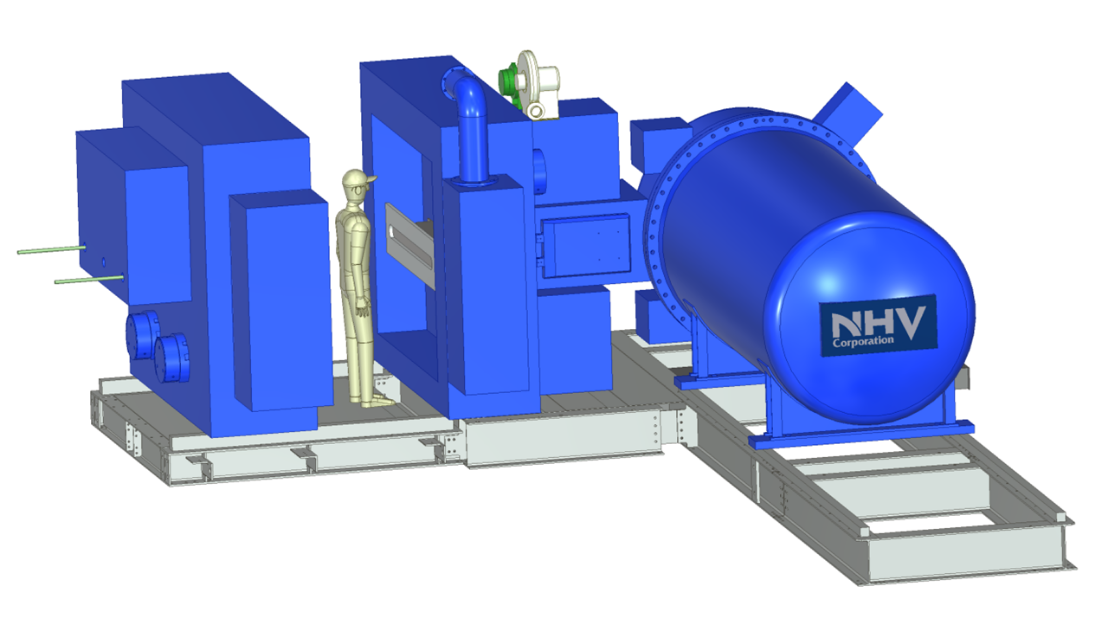

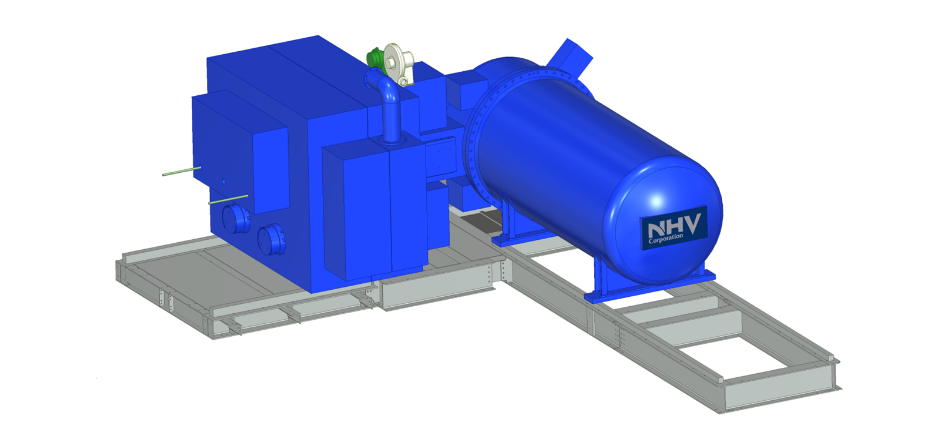

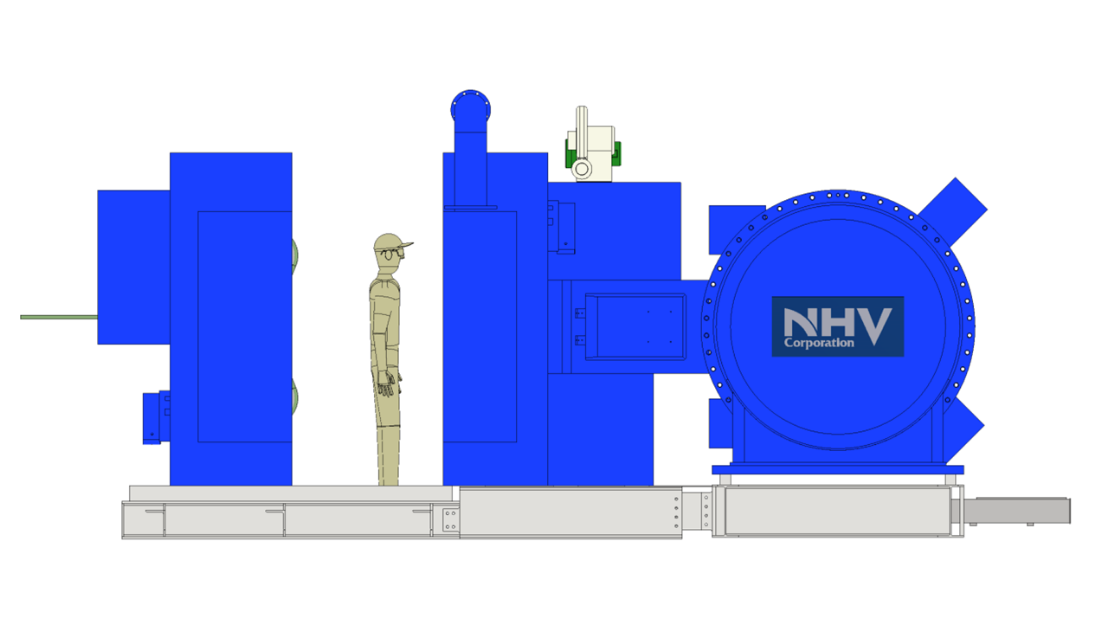

2Ensuring safety during maintenance by working in open spaces

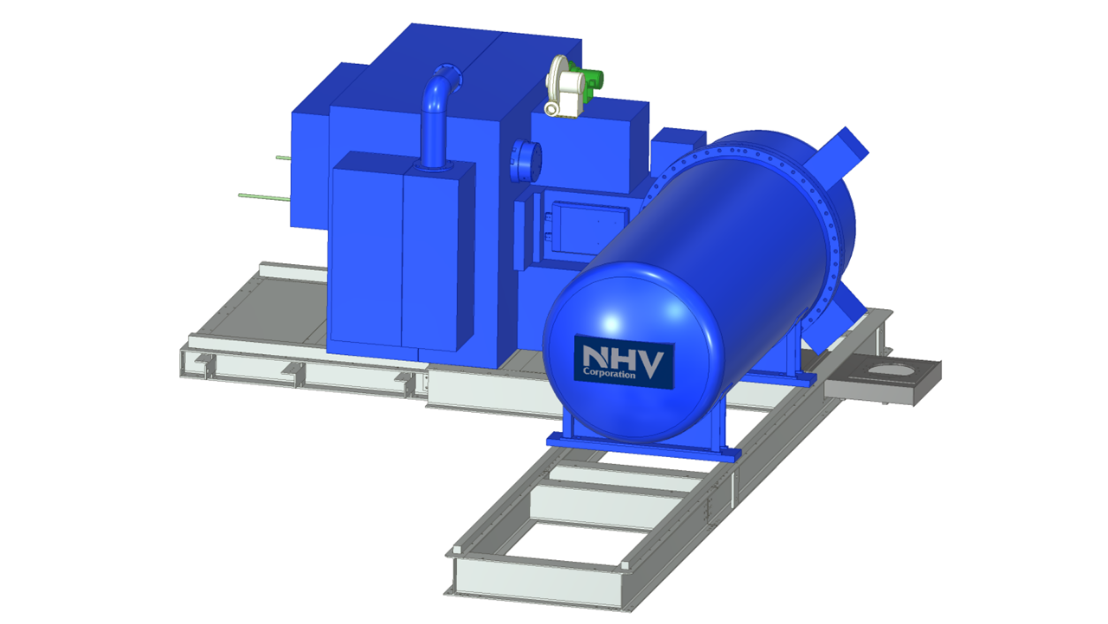

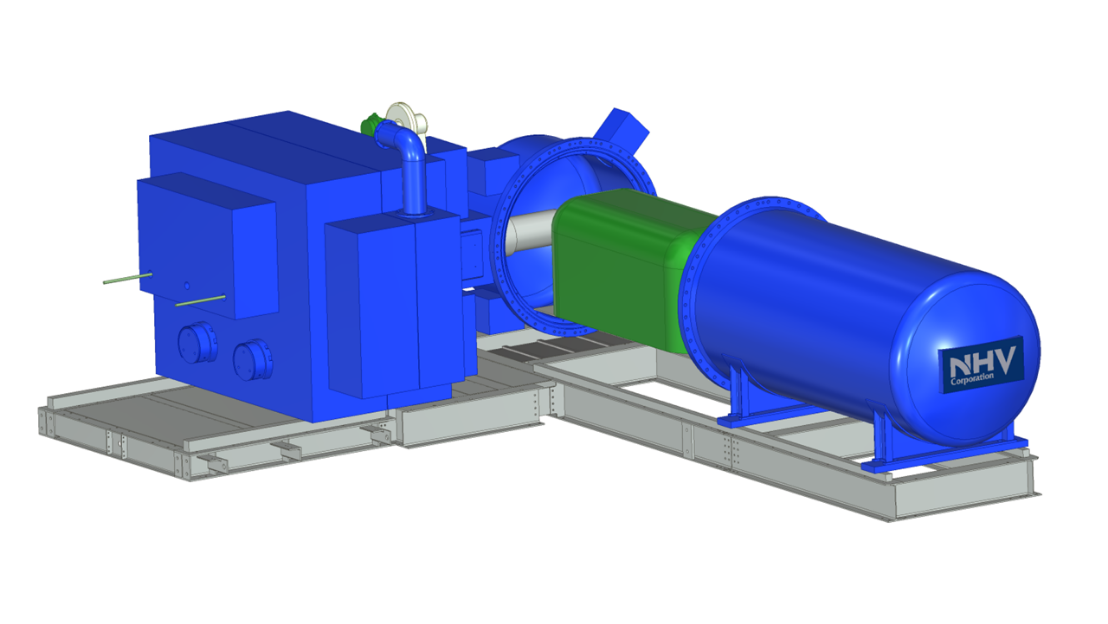

With the EB-XW, ACC Tank and DC tank can be pulled out.

Maintenance work of the accelerator system is possible in the open space.

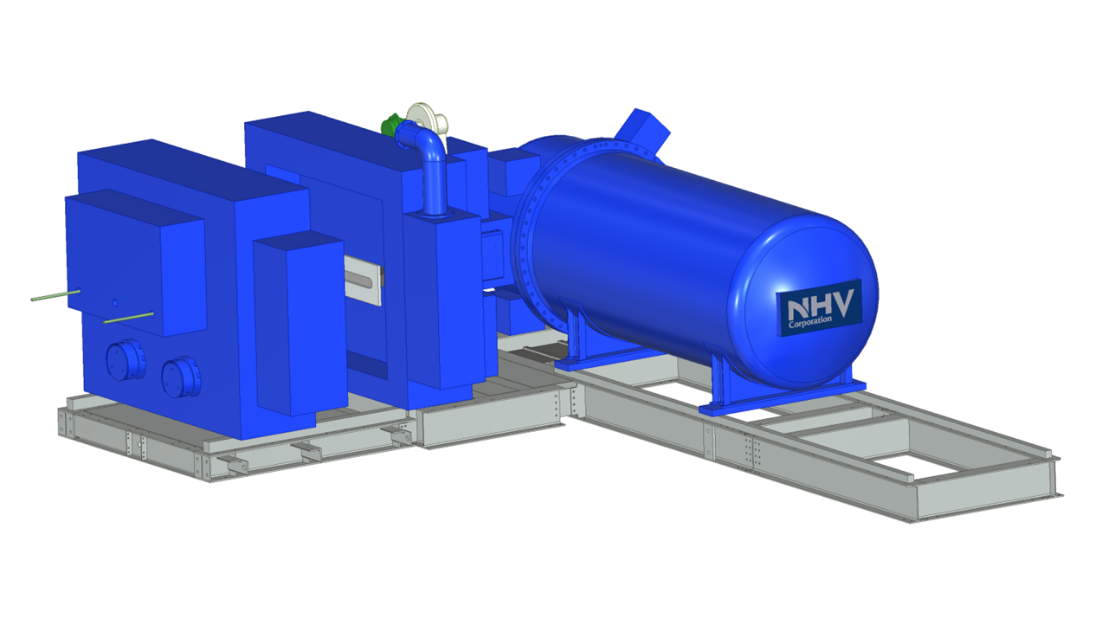

The irradiation chamber can be moved to provide a large space for

maintenance of the handling system and EPS.

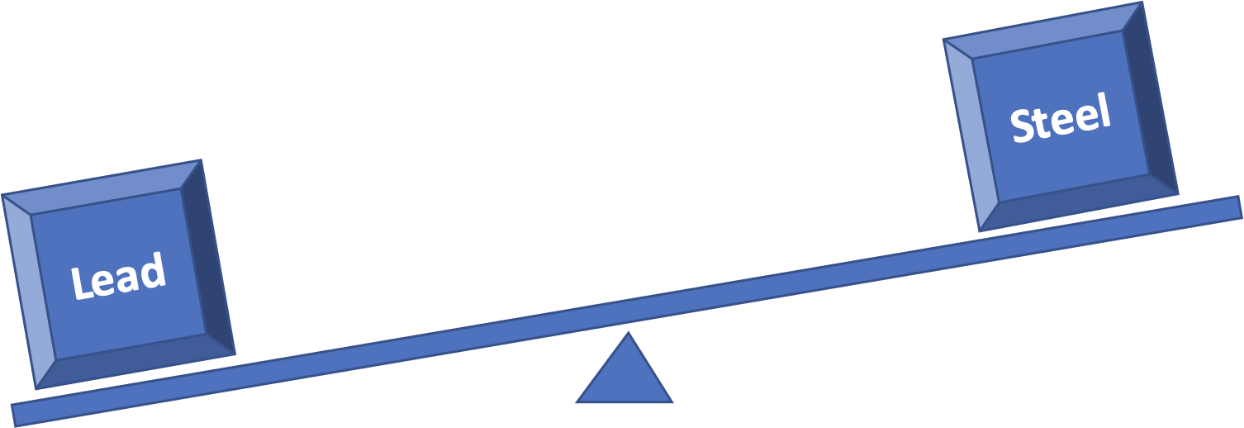

3Changed the main shielding material from lead to steel to reduce price and consider the environment.

- ・Cost reduction

- ・Consider the environment

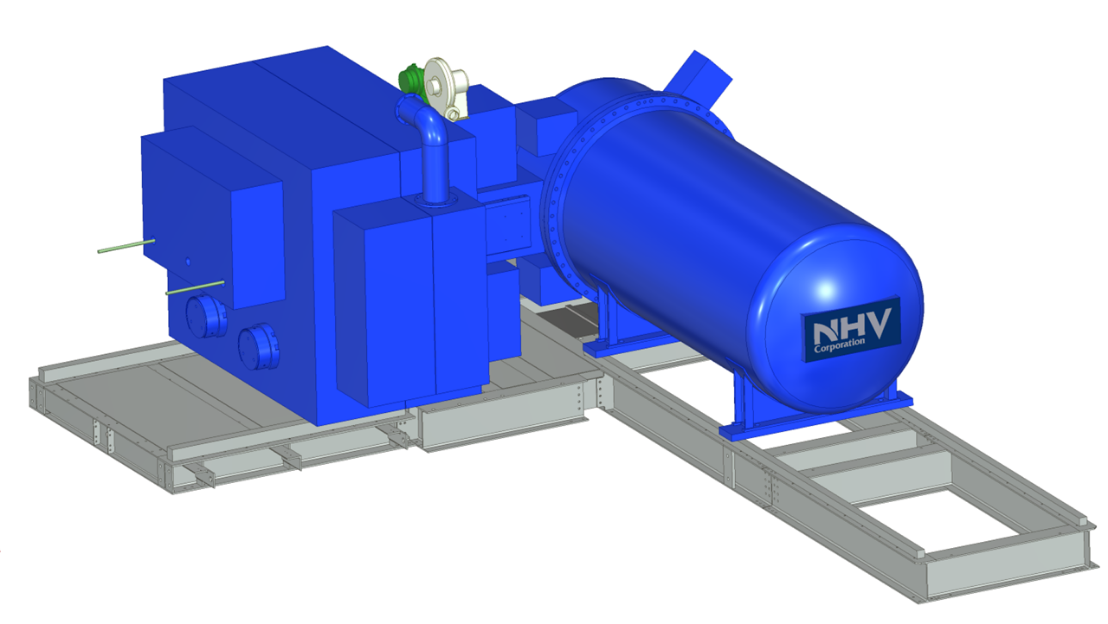

Production Machine Example

| Model | EB-XW 800 |

|---|---|

| Acceleration Voltage |

800kV |

| Irradiation Width |

120cm |

| Device Dimensions |

W6800 × D8200 × H3000mm |